HQ / Seoul

+82-2-2082-5420

| Material | Diameter(mm) |

|---|---|

| Stainless Steel #304 Soft | 0.08, 0.11 |

| Sn Plated Cu | 0.12 |

| TCS | 0.12 |

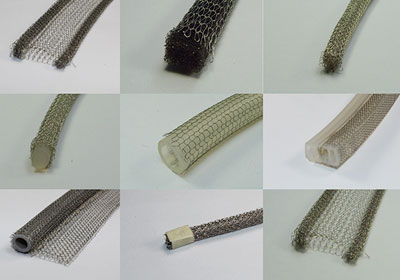

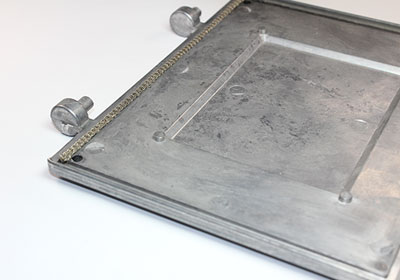

Rectangle Type

(Core material: sponge)

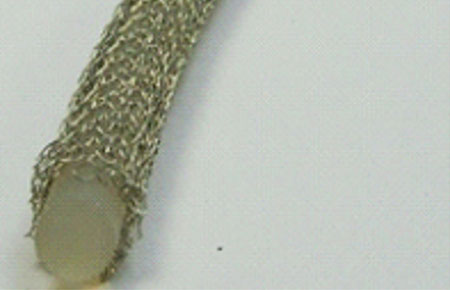

Round Type

(Core material: sponge)

Round Type

(Core material: silicone tube)

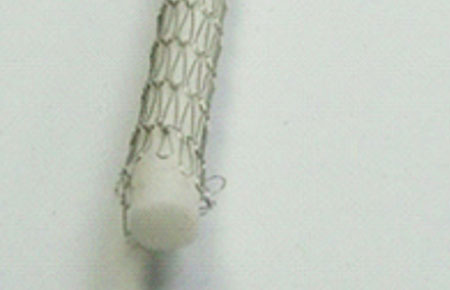

Round Type

(Core material: silicone solid)

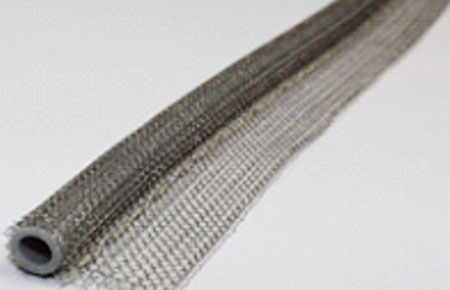

Round Type

(Core material: all mesh)

Square Type

(Core material: all mesh)

P Type

(Core material: silicone tube)

Double P Type

(Core material: all mesh)

* Other shapes, sizes, and materials are available in addition to the above.

Wire mesh gasket is attached to metal frame grooves to improve shielding rate by blocking the gap between frames. Various types of products can be used depending on the frame type.

| Number | Code | Example | |

|---|---|---|---|

| (1) | Product Code | M (Metal Wire Mesh Gasket) | |

| (2) | Serial Number | 415 | |

| (3) | Shape | S: Square (Rectangular) Shape R: Round (Circular) Shape P: P Shape |

DP: Double P Shape A: All Wire Rectangular Shape B: All Wire Circular Shape |

| (4) | Core Material | AW: All Wire PU: PU Sponge SF: Silicone Foam Sponge LTX: Latex |

SH: Silicone Rubber Sponge EM: EDPM Sponge CR: CR Sponge S: All Silicone |

| (5) | Wire Layer | 1: Single Layer, 2: Double Layers | |