HQ / Seoul

+82-2-2082-5420

* Options available such as plate material, core, edge plating, O-Rings, etc.

| Options | Codes | |

|---|---|---|

| Product Code | S: Spiral spring gasket | |

| Strip(Ribbon) Material | BT: Sn plated BeCu, BN: Ni plated BeCu, SN: Stainless Steel | |

| String OD (Ø) | 010~100 (1.0~10.0mm) | |

| Core Material | W: Cordless, T: Silicone rubber tube, A: Silicone rubber solid, F: Silicone foam | |

| Options | O-Rings* | R: O-Ring inner diameter(mm), * String type unless indicated |

| Edge Plating | E: Edge plating, * No edge-plating unless indicated | |

* Product code examples (Options selected)

SBT-025T: Sn plated BeCu + String OD(Ø) 2.5mm + Silicone rubber tube

SBT-025T-E: Sn plated BeCu + String OD(Ø) 2.5mm + Silicone rubber tube + Edge plating

SBT-025T-R050: Sn plated BeCu + String OD(Ø) 2.5mm + Silicone rubber tube + O-Rings (ID 50mm)

SBT-025T-E-R050: Sn plated BeCu + String OD(Ø) 2.5mm + Silicone rubber tube + Edge plating + O-Rings (ID 50mm)

* O-Rings: Excellent precise welding and durability by spot welding on connection parts

(Depending on the thickness of the string OD, O-Ring’s ID may be limited.)

| Contents | Silicone Foam | Silicone Rubber Tube | Test Method | |

|---|---|---|---|---|

| Core | Color | White | Translucent | - |

| Specific Gravity | 1.16 g/cm3 | 1.16 g/cm3 | JIS K 6220 | |

| Hardness (JIS A) | 53 | 61 | JIS K 6253 | |

| Tensile Strength | 91 Kgf/㎠ | 104 Kgf/㎠ | JIS K 6251 | |

| Elongation | 320 % | 365 % | JIS K 6251 | |

| Strip (Ribbon) | Material | Sn/Ni plated BeCu #C17200 / Stainless steel #304H | ||

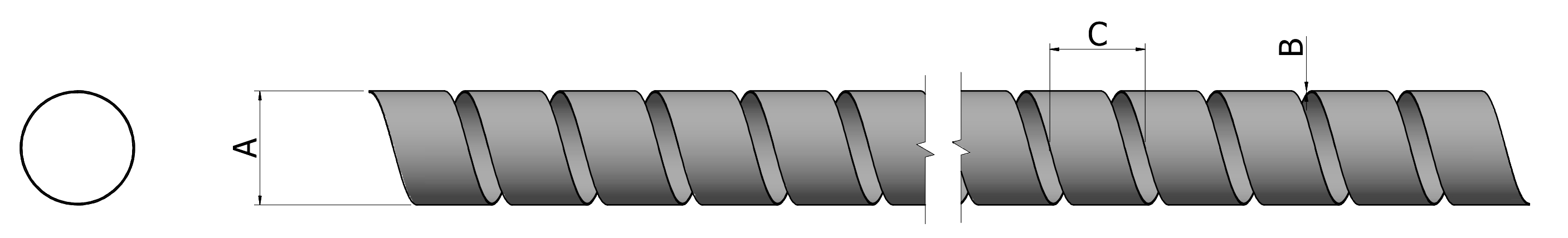

| Item | Unit | SBT-024W | SBN-024W | SSN-024W | Test Method | |

|---|---|---|---|---|---|---|

| Size | Outer Diameter (A) | mm | 2.4±0.1 | ESQ-612-23 | ||

| Thickness (B) | mm | 0.08±0.004 | ESQ-612-23 | |||

| Pitch (C) | mm | 5±0.4 | ESQ-612-23 | |||

| Standard Length | M/Roll | 30 | ESQ-612-23 | |||

| Vertical Resistance | Ω | < 0.1 | ESQ-612-02 | |||

| Compression Recovery Rate (25%, 150℃X100hr) |

% | > 90 | ESQ-612-18 | |||

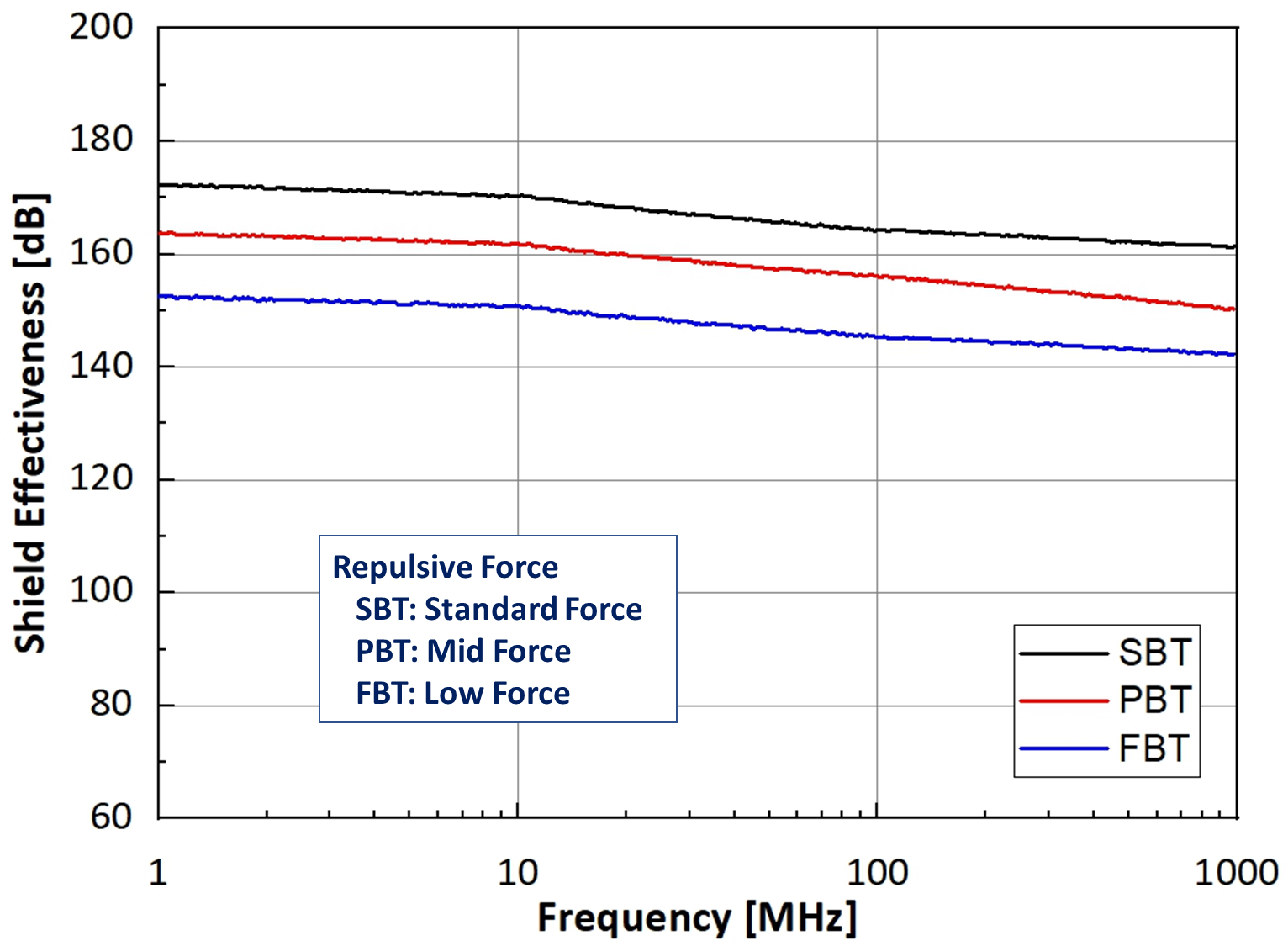

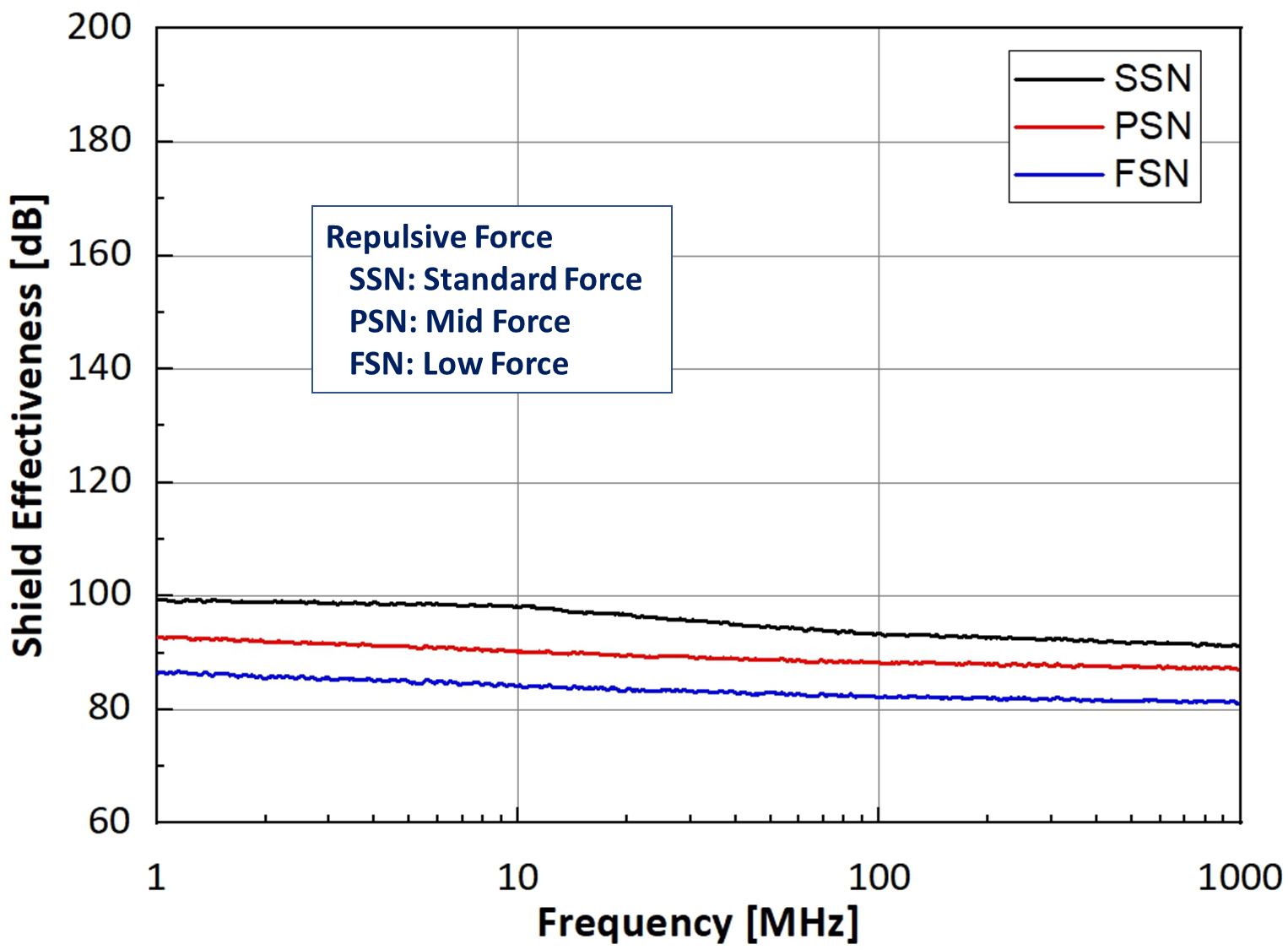

| Compression Force (25%) | Kgf/in. | 8.0±15% | 7.5±15% | 10.0±15% | ESQ-612-27 | |

| Material | - | Sn plated BeCu | Ni plated BeCu | Stainless Steel | - | |

| Environment Friendly | RoHS compliant | - | ||||

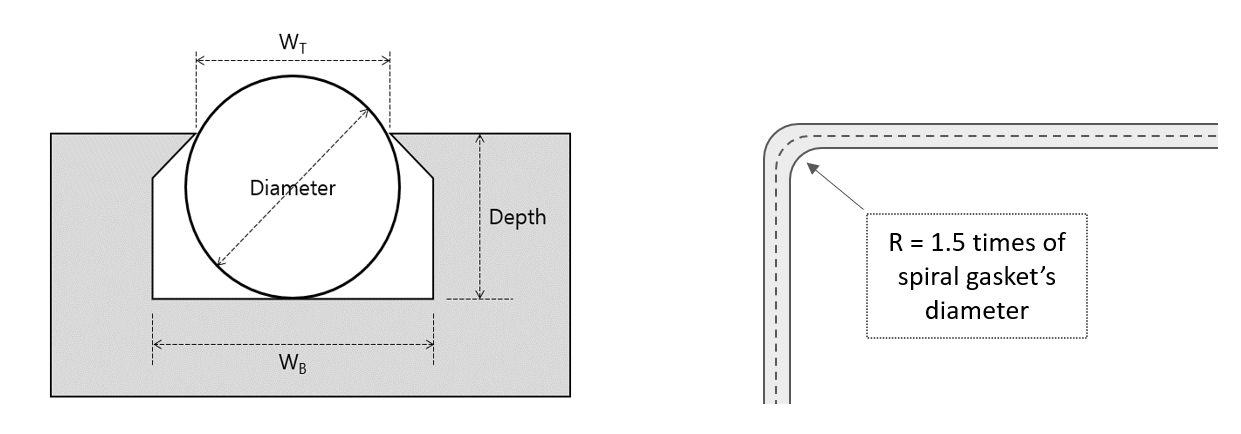

| Outer Diameter[mm] | Recommended Groove Size[mm] | ||

|---|---|---|---|

| Depth | WB | WT | |

| 1.0 | 0.75 | 1.35 | 0.96 |

| 2.0 | 1.50 | 2.70 | 1.92 |

| 2.2 | 1.65 | 2.97 | 2.11 |

| 2.4 | 1.80 | 3.24 | 2.30 |

| 2.6 | 1.95 | 3.51 | 2.50 |

| 2.8 | 2.10 | 3.78 | 2.69 |

| 3.0 | 2.25 | 4.05 | 2.88 |

| 3.2 | 2.40 | 4.32 | 3.07 |

| 3.4 | 2.55 | 4.59 | 3.26 |

| 3.6 | 2.70 | 4.86 | 3.46 |

| 3.8 | 2.85 | 5.13 | 3.65 |

| Outer Diameter[mm] | Recommended Groove Size[mm] | ||

|---|---|---|---|

| Depth | WB | WT | |

| 4.0 | 3.00 | 5.40 | 3.84 |

| 4.2 | 3.15 | 5.67 | 4.03 |

| 4.4 | 3.30 | 5.94 | 4.22 |

| 4.6 | 3.45 | 6.21 | 4.42 |

| 4.8 | 3.60 | 6.48 | 4.61 |

| 5.0 | 3.75 | 6.75 | 4.80 |

| 6.0 | 4.50 | 8.10 | 5.76 |

| 7.0 | 5.25 | 9.45 | 6.72 |

| 8.0 | 6.00 | 10.80 | 7.68 |

| 9.0 | 6.75 | 12.15 | 8.64 |

| 10.0 | 7.50 | 13.50 | 9.60 |

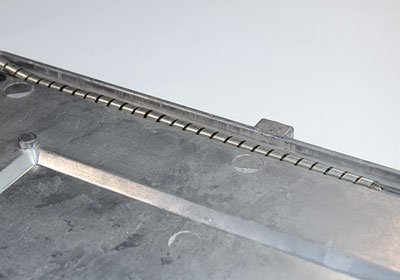

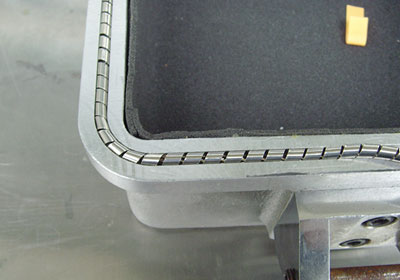

It is mainly used in precision equipment sensitive to electromagnetic waves, such as semiconductor manufacturing equipment, display production equipment, and telecommunication equipment.

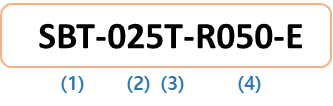

| Number | Code | Example | |

|---|---|---|---|

| (1) | Metal Material | SBT: Sn plated BeCu SBN: Ni plated BeCu SSN: Stainless Steel |

|

| (2) | Outer Diameter | 025: 2.5mm | |

| (3) | Cord Material (See below.) |

W: Cordless T: Silicone rubber tube |

F: Silicone foam A: Silicone rubber solid cord |

| (4) | Options | R: O-Ring type 050: O-Ring ID 50mm |

E: Edge plating |

W: Cordless

F: Silicone Sponge

T: Silicone Rubber Tube

A: Silicone Rubber Solid

| OD(Ø)* | Stainless Steel | Tin-plated Be/Cu | ||||

|---|---|---|---|---|---|---|

| Standard Force | Mid Force | Low Force | Standard Force | Mid Force | Low Force | |

| Ø 1.0 | SSN-010W | PSN-010W | - | SBT-010W | PBT-010W | - |

| Ø 2.0 | SSN-020W | PSN-020W | - | SBT-020W | PBT-020W | - |

| ~ | ~ | ~ | ~ | ~ | ~ | ~ |

| Ø 9.0 | SSN-090W | PSN-090W | FSN-090W | SBT-090W | PBT-090W | FBT-090W |

| Ø 10.0 | SSN-100W | PSN-100W | FSN-100W | SBT-100W | PBT-100W | FBT-100W |

* Outer diameter can be manufactured in increments of 0.1mm.