Our R & D center conducts reliability testing on a regular basis to provide more stable quality products to customers.

The reliability tests that we mainly carry out are as follows.

SEM/EDS

XRF (X-ray Fluorescence)

Resistance Compression Test

EMI Shielding Performance Test

Surface Resistance Test

Volume Resistance Test

Compression Recovery Test

Magnetic Shielding Performance Test

Thermal Conductivity Test

Lead wettability measurement

Ageing Test

Plating Adhesion Strength Test

SEM/EDS

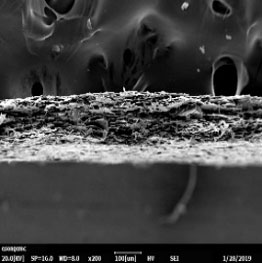

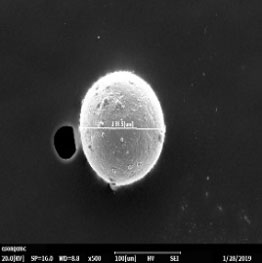

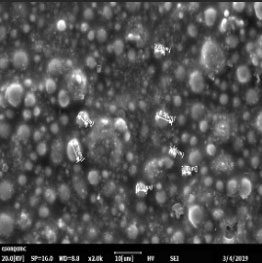

Scanning Electron Microscopy (SEM)

SEM analyzes the surface of sample through secondary electrons or reflection electrons generated from the sample by scanning electron beam on the surface of the sample.

It is possible to measure the shape and particle size of the surface of the sample.

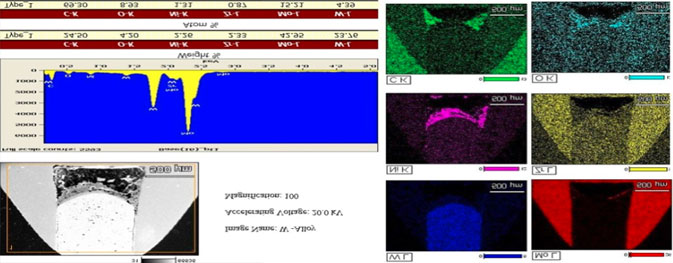

Energy Dispersive X-Ray Spectroscopy (EDS)

EDS conducts elemental and quantitative analysis of sample products from Element No. 5 B (Boron) to 98 Cf (Californium).

SEM Image Sample

EDS Image Sample

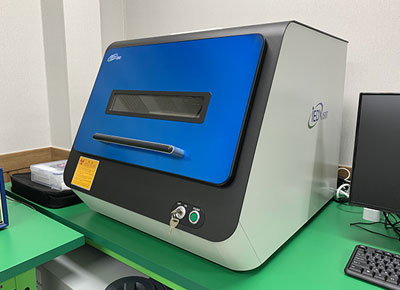

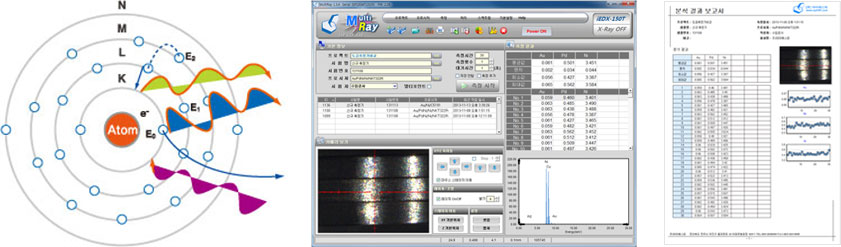

XRF (X-ray Fluorescence)

- Multilayer thin film thickness measurement (maximum 5 layers)

- Analysis of hazardous materials (Cr, Br, Cd, Hg, Pb, Cl, Sb, Sn, S, etc.) for RoHS, WEEE and ELV

- Measurement range: Ti (22) to U (92)

- Sample form: solid / liquid / powder

※ Measurement principle

X-ray fluorescence (XRF) is the emission of characteristic "secondary" (or fluorescent) X-rays from a material that has been excited by being bombarded with high-energy X-rays or gamma rays. The phenomenon is widely used for elemental analysis and chemical analysis, particularly in the investigation of metals, glass, ceramics and building materials.

When materials are exposed to short-wavelength X-rays or to gamma rays, ionization of their component atoms may take place. Ionization consists of the ejection of one or more electrons from the atom, and may occur if the atom is exposed to radiation with an energy greater than its ionization energy. X-rays and gamma rays can be energetic enough to expel tightly held electrons from the inner orbitals of the atom. The removal of an electron in this way makes the electronic structure of the atom unstable, and electrons in higher orbitals "fall" into the lower orbital to fill the hole left behind. In falling, energy is released in the form of a photon, the energy of which is equal to the energy difference of the two orbitals involved. Thus, the material emits radiation, which has energy characteristic of the atoms present. The term fluorescence is applied to phenomena in which the absorption of radiation of a specific energy results in the re-emission of radiation of a different energy (generally lower).

* Source : wikipedia.org

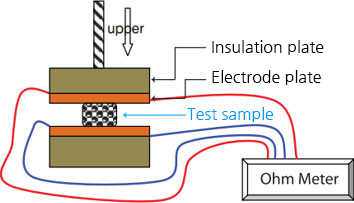

Resistance Compression Test (ESQ-517-27)

- Electrode plate size : 25mm x 50mm x 10mm

- Electrode material : Gold plated copper

- measuring range : 0.1μΩ ~ 110MΩ

- Sample size : L50mm (Standard specimen size of fingerstock : 1~3pins)

Test method

Insert sample between electrode plates. Press the upper plate down, measuring vertical resistance, force and pressing rate simultaneously. Load and other settings are set to match the samples size and type.

Test object

Thick and flexible products such as fabric over foam and fingerstock

Test sample size : 1.0mm ~ 30mm think and 50mm long

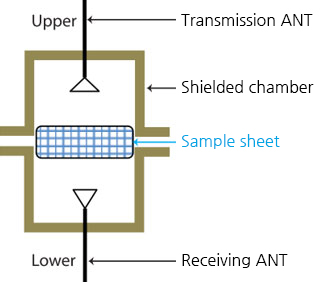

EMI Shielding Performance Test

ASTM D 4935

- Measured range : 30MHz~1GHz

- Sample size : D130mm

Test method

Insert sample sheet (O.D. 130mm, I.D. 70mm) into the shielded chamber and measure S.E. with network analyzer. Insert sample sheet (O.D. 130mm) and measure S.E. Compare the results and calculate shielding effectiveness.

Test object

Products which is less than 2mm thick such as conductive fabric, conductive mesh, conductive film and conductive tape

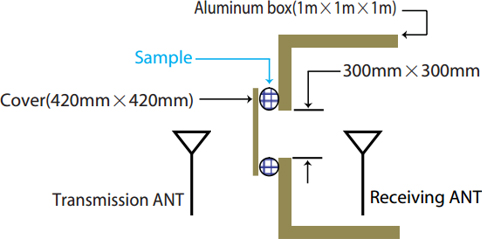

Advantest

- Measured range : 10MHz~1GHz

- Sample size : 150mm x 55mm

Test method

The same method as MIL MIL DTL-83528C. Low frequency test available (from 10KHz)

Test object

Conductive mesh, conductive film, conductive thin sheet, military-used shielding material

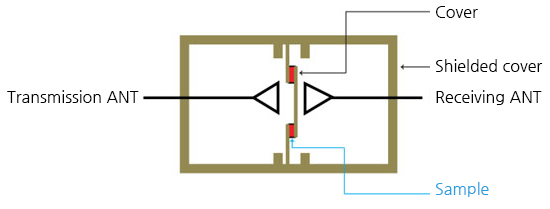

ESQ-517-28 (MIL DTL-83528C Equivalent)

- Measured range : 100MHz~6GHz

- Sample size : 400mm x 400mm

Test method

For measuring wide range frequency

Test object

Fabric over foam, fingerstock, wire mesh gasket, bigger product

Surface Resistance Test (ESQ-517-04)

*Refer to ASTM D 257-99

- Measured range : 30mΩ~30KΩ

- Sample size : 50mm x 50mm

Test method

Test object

Conductive fabric, conductive non-woven, conductive adhesive tape, conductive thin sheet

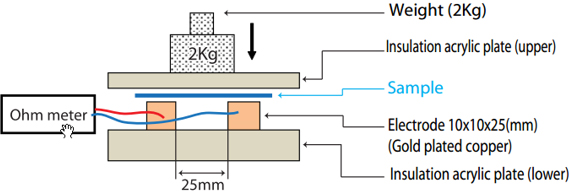

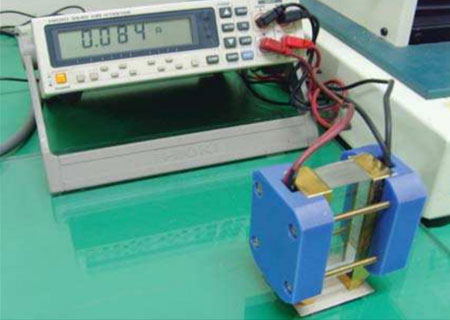

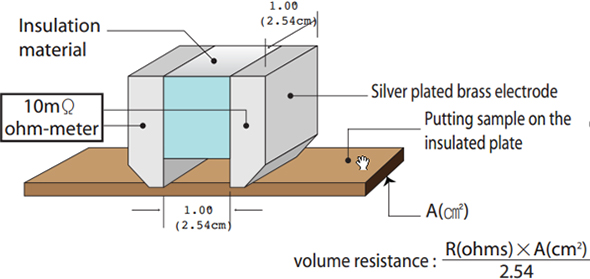

Volume Resistance Test (MIL-DTL-83528C(ASTM D991-Low Resistance Domain), ASTM D257)

- Measuring range : 30mΩ~30KΩ

- sample size : 50mm x 50mm

- Electrode weight : 200g~240g

Test method

Put down the sample on the insulation plate and put electrode on the center of sample and measure resistance

Test object

Products which is electrically conductive itself such as conductive silicone elastomer and conductive foam

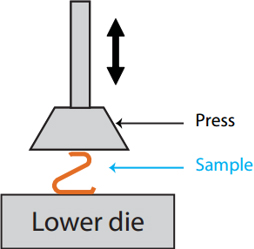

Compression Recovery Test (ESQ-517-26)

- Cycling speed : Max 4cycle/sec

- Pressing material : stainless steel

Test method

This is to test its life cycle concerning restoration. put the sample on the lower die and compress cycle/sec to 30% of its free standing height

Test object

Products where recovery rate is important, such as fabric over foam gaskets and fingerstock

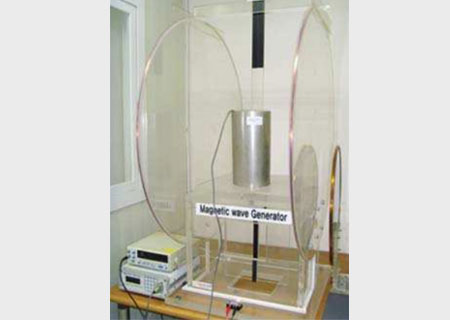

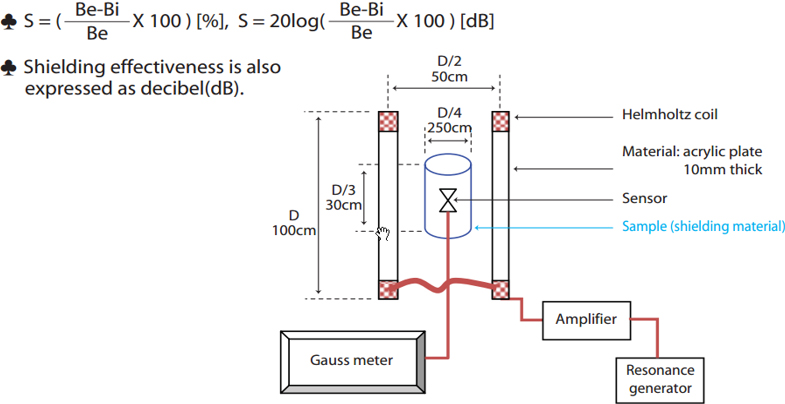

Magnetic Shielding Performance Test (ASTM A698-92)

- Frequency range : 10Hz~10KHz

- Measuring range : 0.1mG~10G

- Sample size(D/4) : Φ250mmX300mm

- Sample shape : cylinder

Test method

Put the sample in the center of Helmholtz coil and generate alternative magnetic field to sample. Magnetic shielding effectiveness(S) is expressed as below formula which means the difference between the strength(Be) of magnetic field measured without shielding material and the strength(Bi) measured covered.

Test object

Products which has permeability such as permalloy foil, MAGshiel foil, Si-steel. etc.

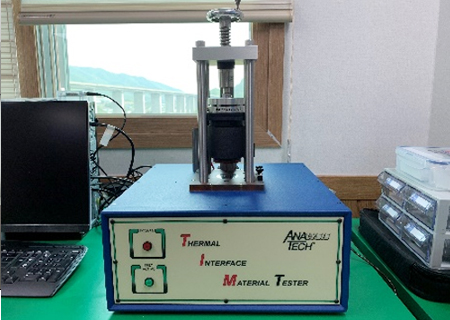

Thermal Conductivity Test

- Thermal Conductivity Measurement: 0.1W/mK ~ 100W/mK

- Thermal resistance measuring range: 0.01K/W ~ 8K/W

- Measurable material: Solid, Powder, Liquid

- Measurable thickness: 50㎛ ~ 20mm

- Measuring pressure: 10psi ~ 150psi (Possible to measure thickness and thermal resistance of specimen under pressure changes)

Principle of operation

This thermal conductivity measuring instrument can measure the thermal conductivity of various materials by using the thermal equilibrium method according to US ASTM-D5470 standard. This apparatus is based on the determination of the thermal conductivity of the specimen at the moment when the heat quantity in the upper and lower parts becomes equilibrium.

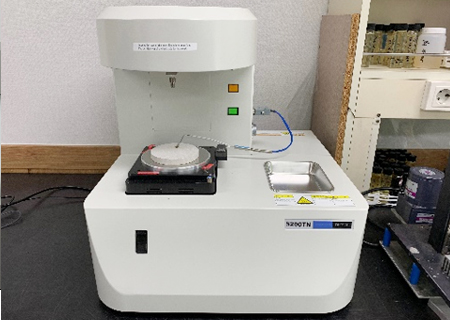

Lead Wettability Measurement

- Usage:

- Specification: penetration depth 0.01 ~ 20.0mm

- Penetration rate: 0.1 ~ 30.0mm / sec

- Dimensions: 467 (W) * 475 (D) * 556 (H) mm

- Pressure sensitivity: 50mN full-scale

- Bath temperature: 245℃ ± 2℃, PID control

Evaluation and measurement of wettability of solder on electronic parts

Measures wetting time, wetting force, contact angle and surface tension

Principle of operation

The sample is hung on the arm of the electronic balance and automatically penetrates into the solder melted up to the set depth by the set speed. At this time, the molten lead is adsorbed on the surface of the electronic component according to the interfacial tension acting on the surface of the electronic component lead, and forms a contact angle. This change is transferred to the electronic balance hanging from the electronic component sample, and by measuring the transferred force, it is possible to continuously obtain changes in the adsorption force and contact angle of the molten lead over time. From this information, various data such as wetting, contact angle, and surface tension are calculated by a computer using a data processing program.

Aging Test (ESQ-517-20)

Test method

It is one of reliability tests. Raise the temperature and humidity rapidly to sample and keep for some time. Observe its shape, conductivity, adhesion, restoration and compare with initial status. The test conditions, time, temperature, humidity are matched to tye to the size and type of the test sample.

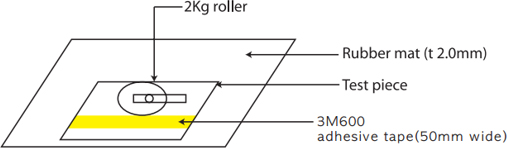

Plating Adhesion Strength Test (ESQ-517-16)

Sample size

W50mm X L50mm

Test method

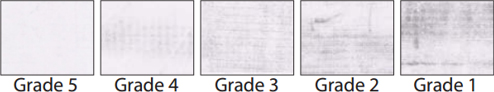

Put the sample on the rubber mat. Attach high adhesion transparent tape (3M600) on the sample and press it 10 times with 2Kg weight roller smoothly back and forth. Remove the tape from the sample slowly. Compare the amount of plating material on the adhesive of the tape with the adhesion standard of plating metal shown below. Rate it from Grade 1 to Grade 5. (Grade 5 is the best and Grade 1 is the worst.)

EX)

Test object

Conductive fabric