Overview

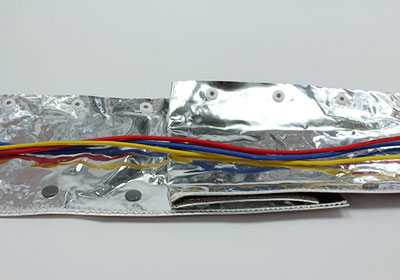

- RF/EMI shielding zipper tube (cable jacket) is used to wrap around a bundle of cables for blocking internal noise radiation or external noise inflow.

- The shielding effectiveness can be increased by adding conductive fabric or wire mesh to the base sheet of aluminum/PVC sheet.

- Suitable for use in cables for semiconductor equipment, power construction, various electrical/communication switchboards, and shield-related construction.

- Zipper tube can be selected for RF/EMI shielding or cable bundling.

Features

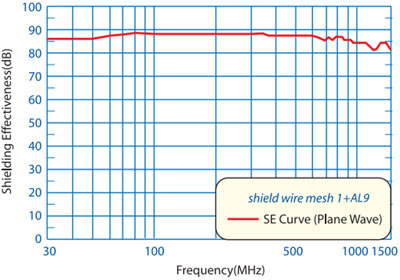

- Excellent shielding effect. (70~90dB attenuation possible in 30MHz~1.5GHz band)

- Grounding is possible by attaching a metal braided wire.

- Easy to install/disassemble/reinstall, and has a great effect on protecting wires.

- Depending on the application, various sheet materials, sizes, and fastening types can be selected.

Details

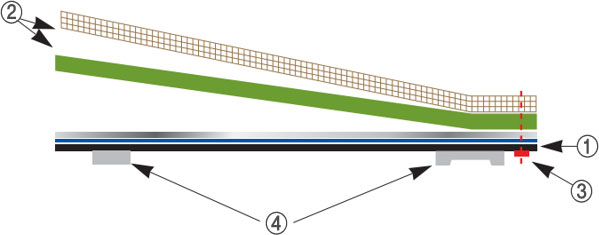

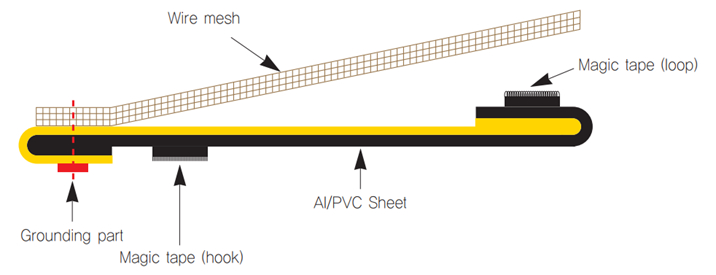

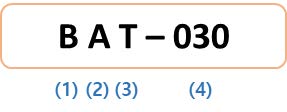

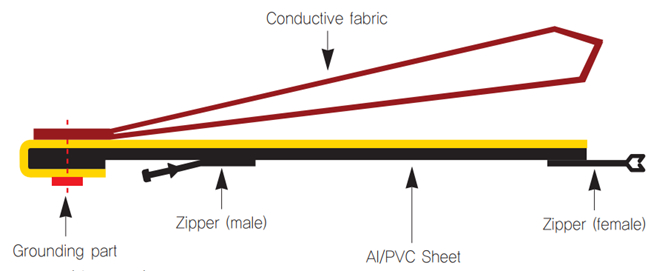

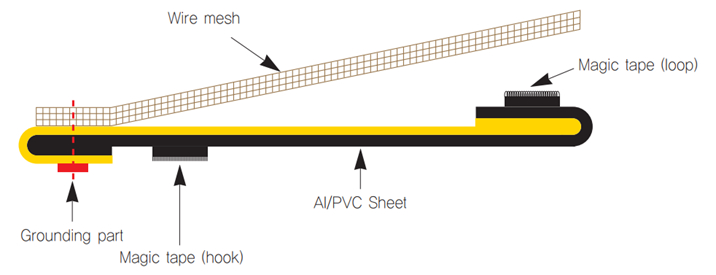

Basic Structure

-

- Base sheet: Aluminum/PVC composite sheet, PVC sheet, Tarpaulin sheet

- Additional sheet: Wire mesh, Conductive fabric

- Ground part: Braided wire (material: tin-plated copper wire)

- Fastening part: Snap button, Velcro, Zipper fastener, Zip lock

Sheet Specifications

| Sheet Type |

RF/EMI Shielding |

Cable Bundling |

| Aluminum/PVC |

PVC |

Tarpaulin |

| Structure |

Aluminum Foil(0.01mm) + PET Film + PVC Film |

PVC Film |

PVC Film + PET Fiber + PVC Film |

| Thickness |

0.24mm |

0.35mm |

0.50mm |

| Operating Temp. |

-15°C ~ +60°C |

-15°C ~ +60°C |

| Flame Retardancy |

UL94 VTM-0 Equivalent |

UL94 VTM-0 Equivalent |

| Additional Sheet |

Al/PVC + Conductive Fabric

Al/PVC + Wire Mesh

Al/PVC + Wire Mesh + Conductive Fabric |

n/a |

| Grounding Part |

Braided wire (Tin-plated copper wire) |

n/a |

Al/PVC+Conductive Fabric

Al/PVC+Wire Mesh

Al/PVC+Mesh+Fabric

Metal Mesh Cover

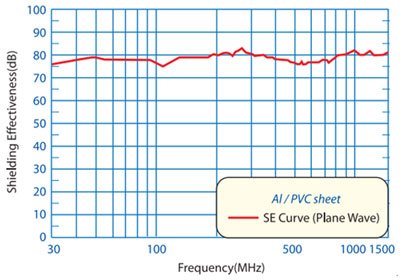

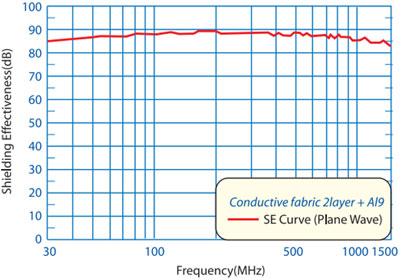

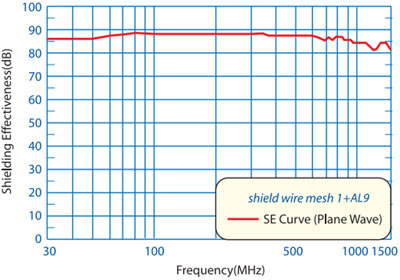

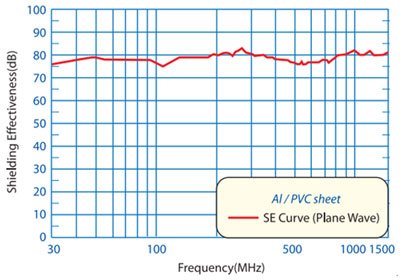

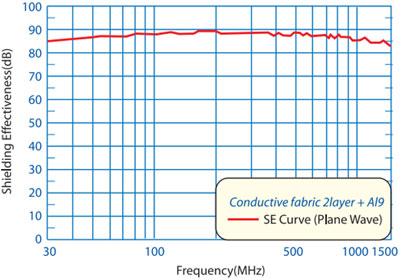

Shielding Effectiveness by Sheet Type

- Shielding performance can be increased by adding metallic materials (conductive fabric, wire mesh) to the Aluminum/PVC base sheet.

| Sheet Type |

Structure |

Noise Attenuation

(30 MHz ~ 1.5 GHz) |

Al/PVC Sheet

(Single Layer) |

|

70 ~ 80 dB |

Al/PVC Sheet + Conductive Fabric

(Double Layers) |

|

80 ~ 90 dB |

Al/PVC Sheet + Wire Mesh

(Double Layers) |

|

80 ~ 90 dB |

- Shielding Effectiveness Graphs

Al/PVC Sheet

Al/PVC+Conductive Fabric

Al/PVC+Wire Mesh

* Test Method: ASTM D 4935

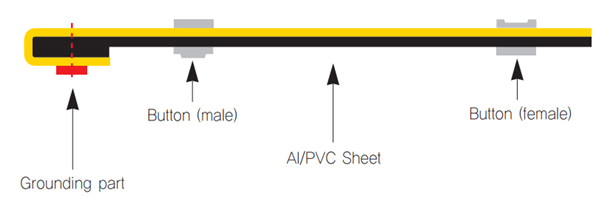

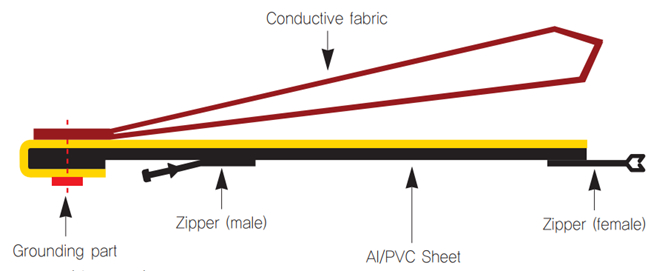

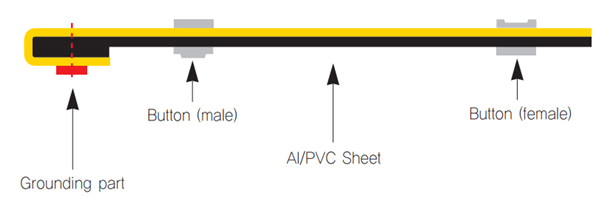

Sheet Fastening Types

- Fastening method can be selected depending on usability.

- Easy to cut appropriately according to the length of wire to be shielded (zipper type requires fixing both ends with stoppers after cutting)

Button (B)

Velcro (M)

Zipper Fastener (F)

Zip Lock (Z)

Product Lines

Applications

How to install

- The diameter after fastening the zipper tube should be about 10-20% larger than the diameter of the wire bundle. If the zipper tube is too tight, the binding/fastening parts might open when the zipper tube is bent.

- After the zipper tube is fastened, the grounding wire(braided wire) attached to the zipper tube should touch the aluminum surface well.

- Fix wires and zipper tube using cable ties at both ends and connect the grounding part of the equipment and the extension cord at the end of the zipper tube.

Precautions (Be careful of leakage through gaps)

- Possibility of leakage from the gap in the fastening area (possibility of leakage from the fastening area, such as between button and button, if the Velcro is not fastened properly)

- If you bend the wire after fastening it, there is a possibility of leakage due to the gap at the fastening area opening.

- If the wires inside the zipper tube are not aligned neatly and are tangled with each other, the gap between the zipper tube and the wires can be large.

Applications

- Examples of a custom large shield cover application

Product Support

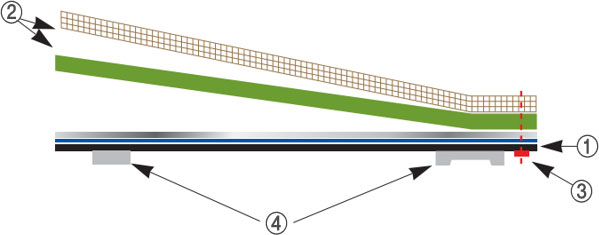

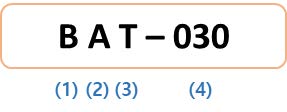

How to select a product number

- Select the base sheet type depending on the purpose, such as shielding cable noise or organizing/protecting wires (Al/PVC, PVC, Tarpaulin)

- Select fastening type (button, Velcro, zipper, ziplock, etc.)

- If high shielding performance is required, select additional sheets (conductive fabric or wire mesh)

Product Number

| Number |

Options |

Codes |

| (1) |

Fastening |

B: Snap button

M: Velcro tape

F: Zipper Fastener

Z: Zip Lock |

| (2) |

Base Sheet |

A: Aluminum/PET/PVC

E: Tarpaulin(0.50mm)

V: PVC Sheet(0.35mm) |

| (3) |

Additional Sheet |

T: No additional sheet

S(2): Conductive Fabric (2 layers)

R(2): Wire mesh 2 layers (1 sheet)

RS(3): Wire mesh 2 layers + Conductive fabric 1 layer |

| (4) |

Size (ID)* |

Inner diameter after fastening, 030: 30mm |

* Since the size (inner diameter) is after fastening, it is recommended to order a size larger than the diameter of the wire bundle.